Sheet metal welding is a process used to join thin metal sheets (such as steel, aluminum, or stainless steel) by applying heat, pressure, or a combination of both. The metal is melted and fused together to form a strong joint. This technique plays a critical role in metalworking and manufacturing.

Working Principle

The fundamental principle of sheet metal welding is to apply high energy to the contact area of the sheets, heating them to their melting point or near it. This creates a weld pool that solidifies upon cooling, bonding the sheets into a single structure.

Types of Equipment

Arc Welder: Uses flux-coated electrodes as the consumable, with an electric arc generating high heat to melt the metal.

Resistance Welder: Relies on heat generated by electrical resistance at the contact surface of the metals.

Laser Welding Machine: Utilizes a high-energy laser beam to melt the metal, enabling high-precision welding.

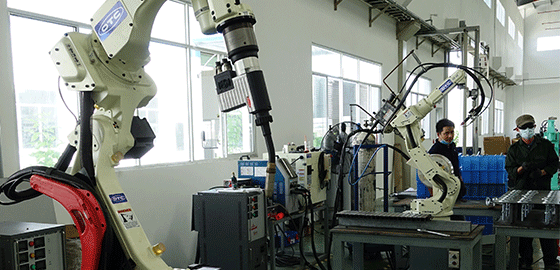

Applications

Automotive Industry: Manufacturing and assembly of car bodies, chassis, exhaust systems, with spot welding and MIG/MAG welding as key techniques.

Home Appliances and Consumer Electronics: Metal housings and internal structures of washing machines, refrigerators, microwave ovens, computer cases, and more.

Machinery Manufacturing: Frames, enclosures, and components of various industrial machines.

Medical Equipment: Joining of metal components in certain precision medical devices.