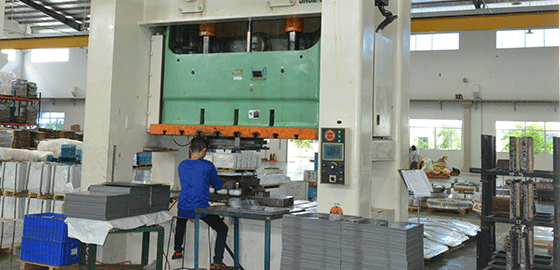

Sheet metal stamping is a metalworking process in which thin sheet materials (such as steel, stainless steel, aluminum, etc.) are placed into a die and subjected to high pressure from a press machine. This pressure causes the metal to undergo plastic deformation or shearing, producing parts in the desired shape.

Working Principle

Working Principle The fundamental principle of sheet metal stamping is the interaction between the die and the press machine, allowing the sheet material to be processed inside the die through: Blanking/Punching: Cutting off portions of the sheet to create holes or separate shapes. Bending: Forming the sheet into the required angles. Drawing: Stretching the sheet into cup- or box-like forms. Forming: Creating more complex three-dimensional shapes, such as corrugations or embossments. Flanging: Turning up edges to increase strength or facilitate assembly.

Types of Equipment

Mechanical Press: Operated by a crankshaft or eccentric wheel; high-speed, suitable for mass production.

Hydraulic Press: Driven by a hydraulic system; stable pressure and controllable stroke, ideal for drawing and forming processes.

Servo Press: Powered by a servo motor; high precision with adjustable speed and stroke.

Applications

Automotive Industry: Car door panels, chassis structures, hoods, wheel arches, reinforcement beams.

Home Appliances: Washing machine housings, air conditioner panels, microwave components, fan covers.

Electronics Industry: Mobile phone casings, computer enclosures, power brackets, heat sinks.

Architecture & Interior Decoration: Elevator door panels, aluminum ceilings, construction connectors.