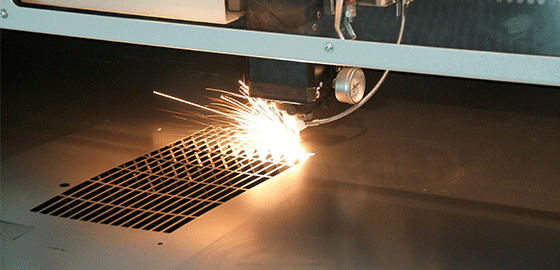

Sheet metal laser cutting is a non-contact machining process that uses a high-energy-density focused laser beam to irradiate the metal sheet, causing localized melting or vaporization. A high-pressure assist gas is simultaneously applied to blow away the molten metal, forming a narrow kerf.

Working Principle

The cutting mechanisms can be classified into two main types: Fusion Cutting: Uses nitrogen or argon as assist gas to blow away molten metal. Suitable for stainless steel, aluminum, copper, and similar materials. Oxidation Cutting (Flame Cutting): Uses oxygen as assist gas, which reacts with iron to produce combustion, thereby increasing the cutting speed of carbon steel.

Types of Equipment

Fiber Laser Cutting Machine

CO₂ Laser Cutting Machine

Applications

Automotive Industry: Car door panels, chassis structures, hoods, wheel arches, reinforcement beams.

Home Appliances: Washing machine housings, air conditioner panels, microwave components, fan covers.

Electronics Industry: Mobile phone casings, computer enclosures, power brackets, heat sinks.

Architecture & Interior Decoration: Elevator door panels, aluminum ceilings, construction connectors.