Powder coating is an eco-friendly and efficient surface finishing technology. It applies dry powder paint onto a workpiece through an electrostatic spraying process, followed by high-temperature baking that melts, levels, and cures the powder to form a durable and uniform coating.

Working Principle

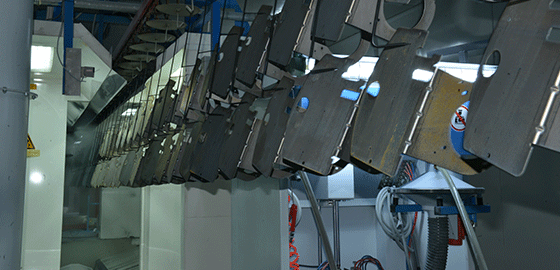

Pre-treatment: A critical step to ensure coating adhesion and durability.

Electrostatic Spraying: Powder particles are charged and applied to the workpiece surface using a specialized electrostatic spray gun.

High-Temperature Curing: The coated workpiece is placed in a curing oven, where heat melts and solidifies the powder into a protective finish.

Types of Equipment

Electrostatic Spray Gun: Used to charge and apply powder particles evenly onto the workpiece.

Curing Oven: Provides controlled high temperatures for melting, leveling, and curing of the powder coating.

Applications

Home Appliances: Refrigerator, washing machine, microwave oven, oven, and air conditioner housings, offering both durability and aesthetics.

Automotive Industry: Wheel rims, frames, chassis components, under-hood parts, and exhaust systems, enhancing corrosion and weather resistance.

Machinery and Equipment: Machine tool enclosures, industrial equipment parts, and agricultural machinery, improving wear and chemical resistance.

Electronics: Computer cases and housings for electronic devices.